Description

| Feature | Description |

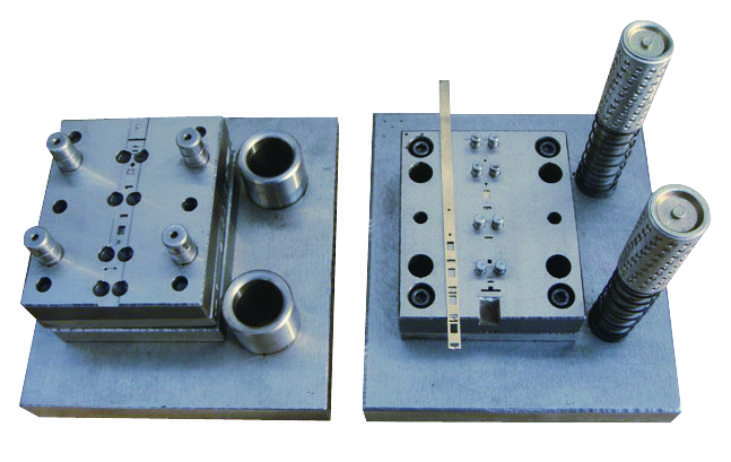

| Mould name | Pressing Puller Mould |

| Model | QLQ-PPM |

| Remark |

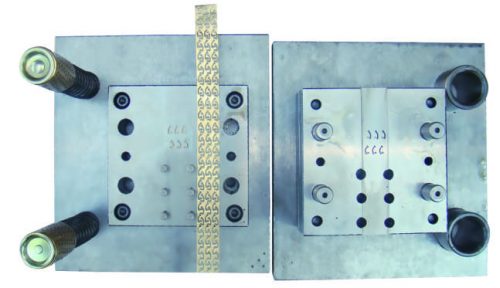

Our state-of-the-art Pressing Puller Mould boasts unparalleled precision, resulting in flawless pullers with every production cycle. Each puller exhibits meticulous attention to detail, leaving no room for defects or imperfections. With our mould, you can produce high-quality pullers that meet the most stringent requirements and delight your customers.

Streamline your puller manufacturing process and boost efficiency with our advanced Pressing Puller Mould. Its cutting-edge design seamlessly integrates into your production line, reducing downtime and maximizing output. Increase productivity without compromising on the quality of your pullers, allowing you to meet high-volume demands with ease.

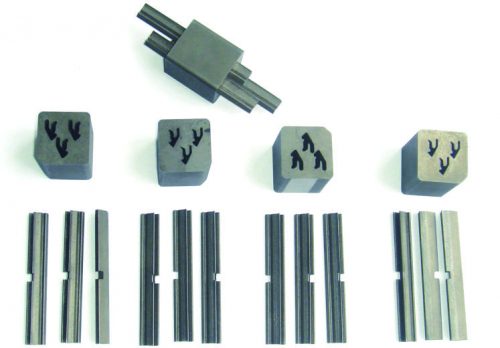

Experience the power of innovative technology with our Pressing Puller Mould. We have leveraged the latest advancements in mould engineering to create a solution that guarantees unmatched performance. From precise alignment to exceptional material distribution, our mould ensures uniformity and strength in every puller produced.

Our Pressing Puller Mould is highly versatile and adaptable to cater to a wide range of puller specifications and designs. Whether you need pullers for apparel, accessories, or industrial applications, our mould can be customized to meet your specific requirements. Stay ahead of market trends and diversify your product offerings with ease and flexibility.

We understand the importance of minimizing downtime and ensuring continuous production. Our Pressing Puller Mould is designed for easy maintenance and seamless repairs, allowing for quick adjustments and component replacements. Keep your production line running smoothly and efficiently, maximizing the uptime of your manufacturing operations. |